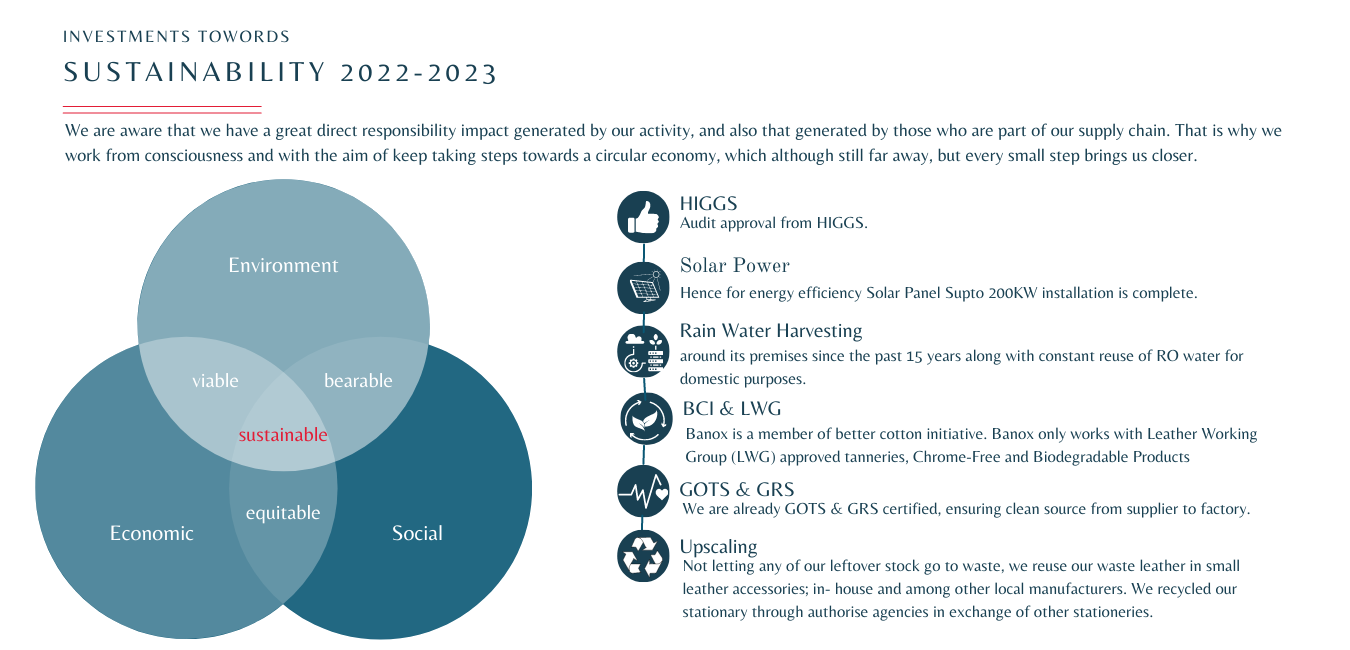

SUSTAINABILITY

WHAT SUSTAINABILITY MEANS FOR US

At Banox, sustainable manufacturing is at the core of all our operations and it starts right at the procurement stage of raw materials. We strive to create ethical handbags & products using economically sound processes, minimizing the negative environmental impacts on society, while conserving energy and natural resources. Above all, our craftsmen are at the core of our manufacturing process, and thus we treat our employees fairly in order to enhance the community at large.

ECONOMIC IMPACT

Our efforts should lead to Economic impact, which may include creating jobs, driving innovation & investing in infrastructure. Banox employees over 1,500 workers.

SOCIAL IMPACT

We strive to offer our employees good working conditions, respecting human rights, treating our suppliers fairly and ensuring product safety. Manufacturing has been a male dominated industry where we are trying a empower women to work with technical training & providing them with crutch facilities.

ENVIRONMENTAL IMPACT

Our goal is to produce handbags with ethically sourced materials. This means reducing the environmental footprint. Being a green company we replenish underground water by doing rain water harvesting. We reuse Ro water for domestic purposes. For energy efficiency we have installed Solar Panels upto 200 KW. We also use energy saving ED lights all over the factory.

“”We believe in upcycling. This is a process of recovering materials or products that are no longer needed, giving a second life to waste.

We reuse our wasted leather in small leather accessories in-house or among other local manufacturers.

We recycle our stationary through authorised agencies in exchange of other stationeries”

How We Source Our Materials: Traceability and Transparency

Each product that leaves Banox features pristine quality leather and suede, sourced from the best ethical tanneries in India and around the world. When selecting a tannery,

we ensure that each leather supplier has been audited and certified by the Leather Working Group. Ensuring that the leather tanning process is free of chromium.

The LWG group seeks to improve the leather manufacturing industry by creating alignment on environmental priorities, bringing visibility to best practices and providing

suggested guidelines for continual improvement.

SUSTAINABILITY TIMELINE

2019

Social

Company decided about CSR expenditure (amount $38,054 ) on education in agreement with Kalidhar Trust and intend to construct 5 classroom (including but not limited to benches, desk, blackboard or any other thing which is required in class room for students) on second floor for the students of AKAL ACADEMY situated at Village- Habari, Tehsil –Pundri, Dist.-Kaithal.

2020

Environmental

Replaced 1100 Tube-lights with 700 Led lights that consumes only 18 watt per unit energy as compare to 40-watt energy consumption in tube lights.

2021

Environmental

Replaced 100 Clutch motors with Servo motors (Energy saving motor). The Servo Motor only runs when you press the pedal, as compared to the constantly running and power onsuming clutch motors. This makes Servo motors more energy efficient and quieter than a clutch motor.

2022

Environmental

Biggest steps taken towards energy saving : Installation of 200 KW solar panels at facility. Having saving 135-ton CO2 in year 2022 & generating 143431 KWH energy hrough Solar. We are now saving 45% more non-renewable resources as compared to 2021 and 2020.

Social

EYE & EAR TESTING CAMP

An initiative to promote the health and fitness of the employees, we organized a free eye/ear check-up camp in collaboration with a leading eye/ear care company Multisession Ophthalmic Opticians). The Program had several benefits for the employees like FREE Eye/Ear care products to widows and physically handicapped employees.

JACKETS & SHOES DISTRIBUTION

An initiative to motivate the employees of the company and to encourage and boost the work performance of other employees for better results, we organized a woolen ackets & shoes distribution program. All the employees were highly enthusiastic and motivated for this event.

WOMEN EMPOWERMENT

To ensure that all women’s worker receive equal remuneration, treatment and opportunities to fill the position open in our facility. We have set up the committee for women’s to provide safe environment and address the issues (if any) at the workplace. Along with a self-empowerment awareness programme specifically organized for female workers.

OUR INITIATIVE

In line with its management philosophy, Banox aims to continue to be a company that is trusted by society, by committing to compliance with laws and regulations, as well as to highly transparent governance, respect for human rights, health and safety, social contribution and environmental preservation, on the basis of high corporate ethics.

TOWARDS SOCIETY

Swatch Bharat Abhyaan:

As a part to keep India clean Banox invested in a Government School of Manesar inproviding better sanitation facilities for the Students of the School. The “RajkiyaVaristha Madhyamik Vidhyala” a government school was facing problem in providingpreventive health care & daily sanitation facilities to its students more specifically a separate washroom for girls.

Provide Safe Drinking Water:

The school was facing problem of shortage of drinking water for students &approached us to help the school to solve the problem of safe drinking water. We aspart of our CSR activities helped the school & make sure that safe & healthydrinking water is available for everyone at the school.

Asian Educational Charitable Society:

The company has also donated to the Asian Educational Charitable Society as a partof its CSR responsibility so as to enable the society to work in the field of educationin providing better education facilities to the students in need.

GREENIN ITIATIVE

SUSTAINABLE AT EVERY STAGE

Banox focuses on sustainable manufacturing at every step of our manufacturing process. From procurement to packaging Banox aims on being environmentally friendly.

Sourcing

Starting from the material procurement stage Banox uses:

- Leather from LWG approved tanneries

- Chrome-free leather

- Vegan Leather – 80% Eco – Composite (Vegetal, renewable & recycled raw materials) & 20% Water PU

- BCI Cotton Fabric –

- Organic Cotton Fabric from GOTS certified suppliers

- Recycled Cotton Fabric from GRS certified suppliers

- Recycled Polyester Fabric from GRS certified suppliers

- Recycled Hardware, Fillers Adhesives & Edge Colour

Production

Banox takes constant steps towards making their production process more environmentally friendly.

- Replaced 1100 Tube-lights with 700 Led lights that consumes 18 watt per unit as compare to 40-watt energy consumption in tube lights.

- Replaced 100 Clutch motors with Servo motors. Servo Motor only runs when you

press the pedal, vs clutch motors: constantly running. - Installation of 200 KW solar panels at facility. Having saving 135-ton CO2 in year 2022 & generating 143431 KWH energy through Solar.

We are now saving 45% more non-renewable resources as compared to 2021 and 2020.

Packaging

Banox has seen its green initiative through the last stage of finishing & packaging.

- Rain Water Harvesting around its premises since the past 15 years along with constant reuse of RO water for domestic purposes.

- We reuse our leftover leather in small leather accessories in-house and other local manufacturers.

- For our packaging we use recycled paper fillers, polly bags and cartons.

- We recycled our stationary through authorise agencies in exchange of other stationeries.