WHAT WE DO

A STORY ABOUT US

With over a decade of experience in designing and manufacturing bags & accessories for private labels, companies of any size and individual; we have masteredthe art and craft of bags & accessories manufacturing.

WE ARE

MORE THAN JUST HANDBAG

MANUFACTURERS

Formed in 2005. We are of the largest manufacturerof handbags, small leather accessories. Achievinggrowth of over 30% in turnover during the last year,continuously improving. Banox is a green company.We use sustainable solar panels for our manufacturingunit.

WE HAVE

HIGHLY SKILLED EMPLOYEES

& LATEST TECHNOLOGY

Constantly reinvesting in upgrading technology,infrastructure and software for efficient production.Over 1,500 highly skilled workers including designers,merchandisers and production managers We have a special team focus on the new trends,materials and all details.

WE OFFER

SUPERIOR QUALITY PRODUCTS &

TIMELY DELIVERIES

The ability to produce large quantity products -120,000 units per month in-house. Stringent qualitycontrol to meet highest international standards. In-house quality and testing laboratory used for fabricinspection, color matching, color fastness etc.

OUR TEAM

GREENIN ITIATIVE

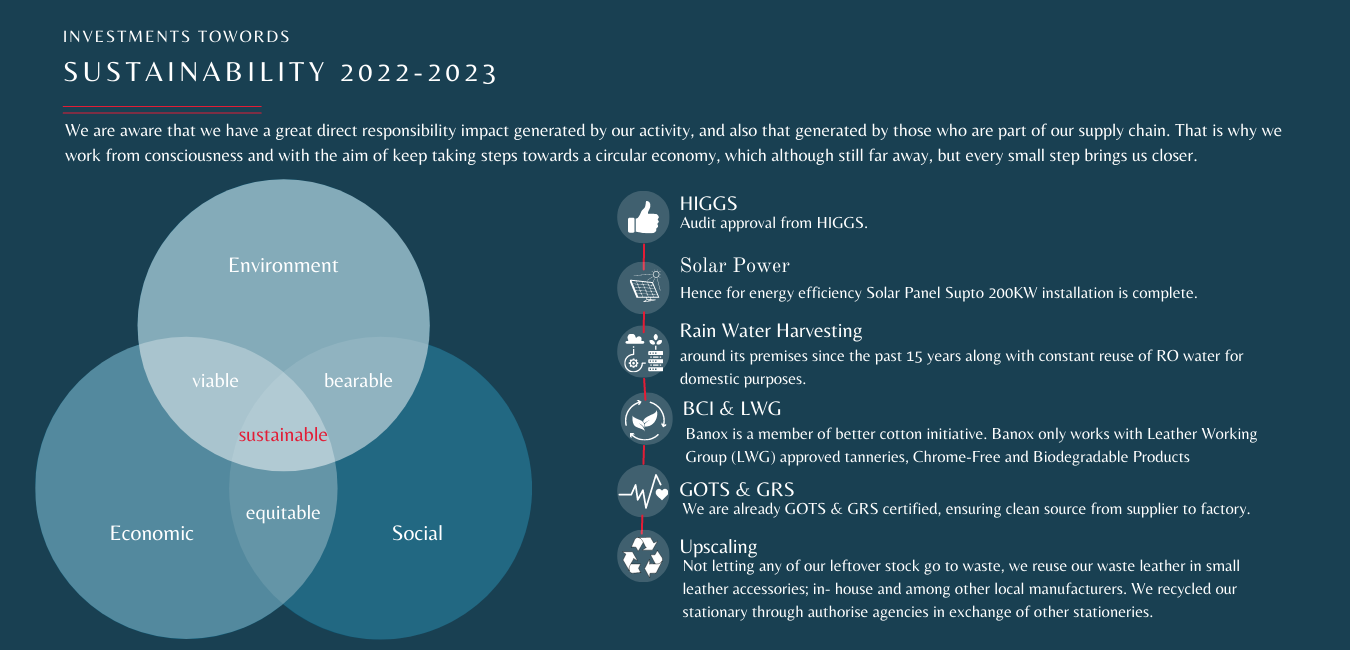

SUSTAINABLE AT EVERY STAGE

Banox focuses on sustainable manufacturing at every step of our manufacturing process. From procurement to packaging Banox aims on being environmentally friendly.

Sourcing

Starting from the material procurement stage Banox uses:

- Leather from LWG approved tanneries

- Chrome-free leather

- Vegan Leather – 80% Eco – Composite (Vegetal, renewable & recycled raw materials) & 20% Water PU

- BCI Cotton Fabric –

- Organic Cotton Fabric from GOTS certified suppliers

- Recycled Cotton Fabric from GRS certified suppliers

- Recycled Polyester Fabric from GRS certified suppliers

- Recycled Hardware, Fillers Adhesives & Edge Colour

Production

Banox takes constant steps towards making their production process more environmentally friendly.

- Replaced 1100 Tube-lights with 700 Led lights that consumes 18 watt per unit as compare to 40-watt energy consumption in tube lights.

- Replaced 100 Clutch motors with Servo motors. Servo Motor only runs when you

press the pedal, vs clutch motors: constantly running. - Installation of 200 KW solar panels at facility. Having saving 135-ton CO2 in year 2022 & generating 143431 KWH energy through Solar.

We are now saving 45% more non-renewable resources as compared to 2021 and 2020.

Packaging

Banox has seen its green initiative through the last stage of finishing & packaging.

- Rain Water Harvesting around its premises since the past 15 years along with constant reuse of RO water for domestic purposes.

- We reuse our leftover leather in small leather accessories in-house and other local manufacturers.

- For our packaging we use recycled paper fillers, polly bags and cartons.

- We recycled our stationary through authorise agencies in exchange of other stationeries.

VISION

Banox aims to become one of the largest manufacturers in south asia of top quality Sustainable handbags. Banox has a long-standing commitment to environmental protection, providing its customers with superior quality products and strives to use innovative products for a greener future. Conducting the business ethically, morally and sustainably as well as maintaining its image withits suppliers, employees and community as a company of excellence.

CONCEPT TO PRODUCTION

5 SIMPLE STEPS

We have a design team to focus on the new trends, materials and latest designs. Our design team is constantly innovation, creating new collections for every season and offer the best selection to our customers. We help our customers find what they are looking for and offer them different options so they can decide what suits their brand essence.